首页-Index

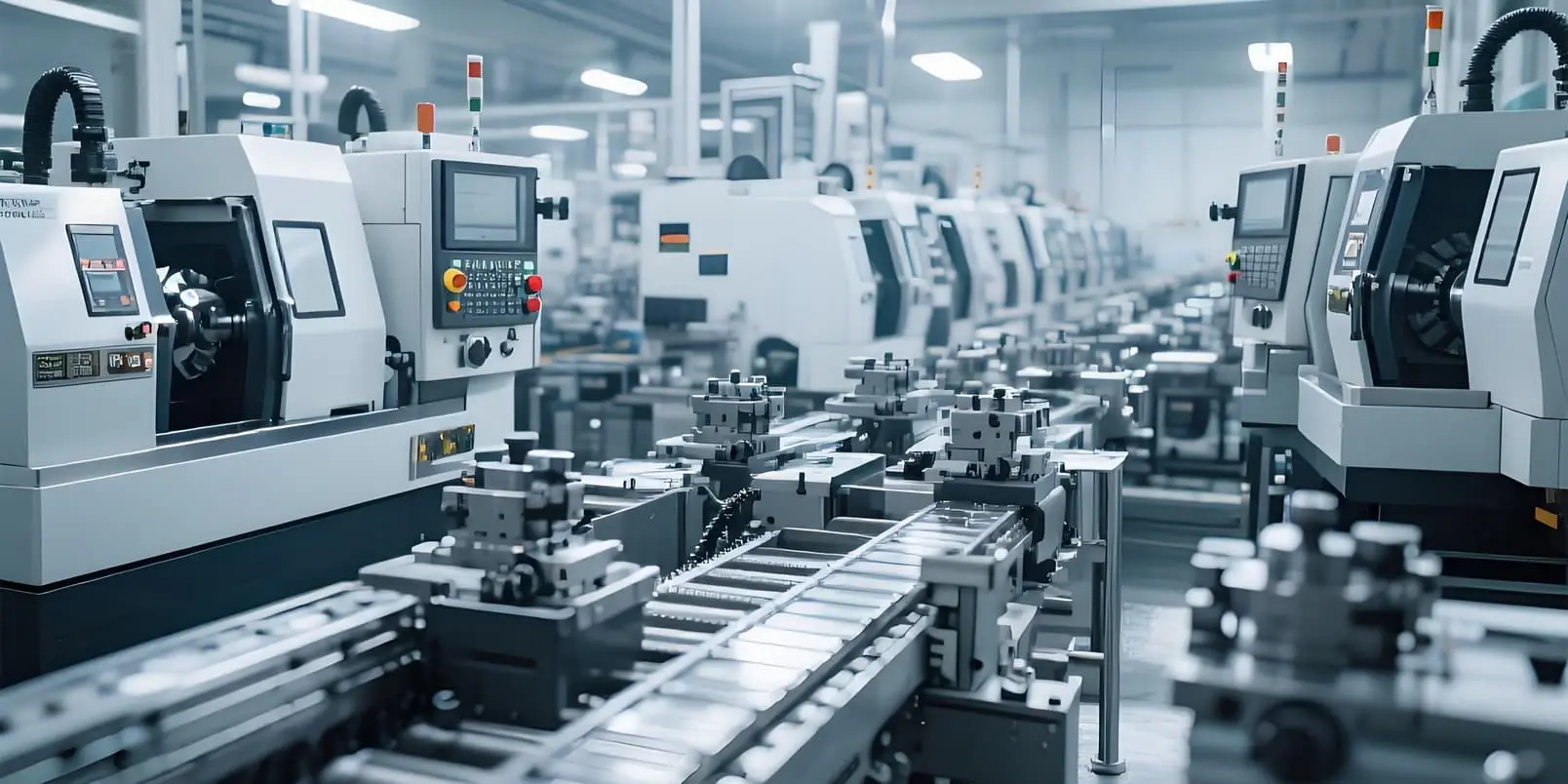

AI工业视觉系统助力中国工业智能制造

Beyond Vision Technology AI vision system helps China’s industrial intelligent-manufacturing.

AI工业视觉检测的6大技术优势

6 Major Technical Advantages of AI Industrial Visual Inspection

效率 Efficiency / 重复性Repeatability

自动化发展提高了效率,对检测提出更高的要求.AI视觉可比人工更快检测产品,特别在生产线上检测高速工作的物体时,机器可以提高检测效率,达到人工的n倍速度;机器可用同样的方法重复性完成检查工作,不感到疲劳。 The advancement of automation has significantly improved efficiency while simultaneously raising higher requirements for inspection. AI vision systems can detect products far more rapidly than human workers, especially when inspecting high-speed moving objects on production lines. Machines can enhance inspection efficiency, achieving speeds multiple times greater than manual labor, and consistently perform repetitive tasks with uniform accuracy without experiencing fatigue.

精度Precision / 成本Cost

在精度方面机器有明显优点,其精度可以达 ±0.001 mm,如果参数设置没有差异,配置多台机器可以保持相同的精度; 前期投入一次性,长期生产,由于AI视觉发展越来越快,价格也会逐渐下降。 Machines hold a significant advantage in terms of accuracy, capable of achieving precision levels as high as ±0.001 mm. If parameters remain consistent, multiple machines can maintain the same accuracy. The initial investment is a one-time cost, and with the rapid advancement of AI vision technology, prices are gradually decreasing, making it highly suitable for long-term production.

客观性 Objectivity

人工检查难免存在漏检,或是人工疲劳等因素。另外有一个致命的缺陷:情绪主观,检查结果随检查员心情的好坏而变化;机器没有喜怒哀乐,它带来的检测结果自然客观可靠。 Manual inspection is prone to missed detections or factors such as human fatigue. More critically, it has a fatal flaw: subjectivity influenced by emotions—results may vary depending on the inspector’s mood. Machines, on the other hand, are free from emotions. The detection results they provide are naturally objective and reliable.

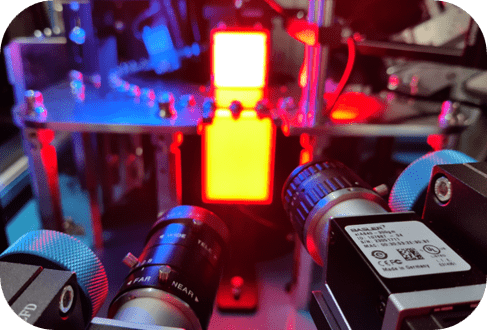

安全性 Safety / 环境 Environment

AI视觉将对象物转换为图像信号,发送至图像处理系统。 在工件测量中,由于不需要与工件接触,因此在能够应对恶劣的危险生产环境的同时,也不会对工件造成接触性损伤。 AI vision converts the target object into image signals and transmits them to an image processing system. In workpiece measurement, since physical contact is unnecessary, it can not only operate effectively in harsh or hazardous production environments but also prevents any physical damage to the workpiece.

信息集成 Information Integration

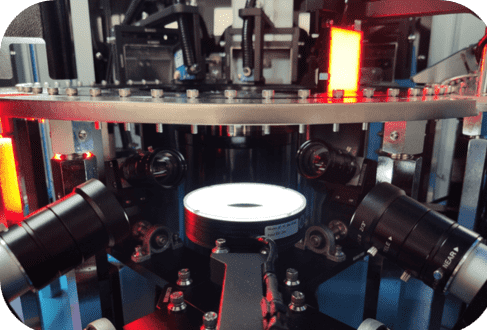

AI视觉可以通过多站检测方法,一次完成被检测产品的轮廓、尺寸、外观缺陷、产品高度及定位等多技术参数的测量,完成全参数化的同时检测及定位,快速准确的集成。 AI vision enables multi-station inspection, allowing for the simultaneous measurement of multiple technical parameters — including contour, dimensions, surface defects, product height, and positioning — in a single process. This ensures fully parameterized inspection and localization with rapid and accurate integration.

数字化 Digital

AI视觉产生的需要测量的数据,可独立复制,也可用网络连接的方式复制,便生产过程的统计和分析。另外也可导出检查后指定的数据来生成报告。不需人工追加,优于人工检查的数据统计。 The measurement data generated by AI vision can be replicated either independently or via network connection, facilitating statistical analysis of the production process. Additionally, specified data after inspection can be exported to generate reports. This method requires no manual intervention and outperforms manual inspection in data statistics.

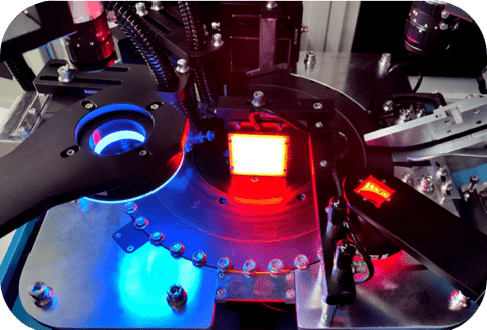

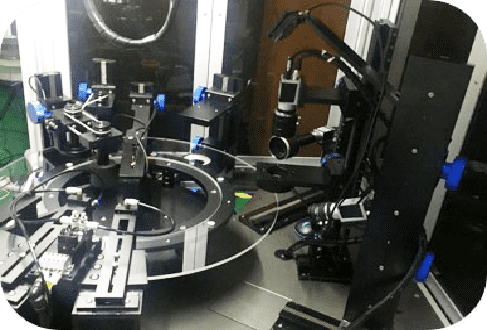

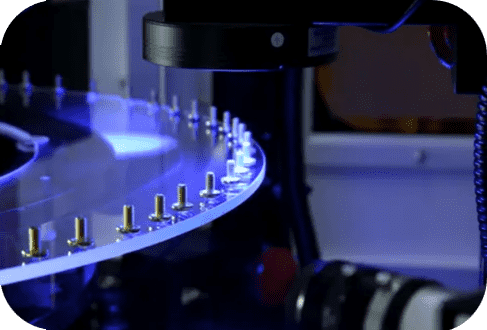

AI工业视觉筛选设备

AI industrial visual screening system

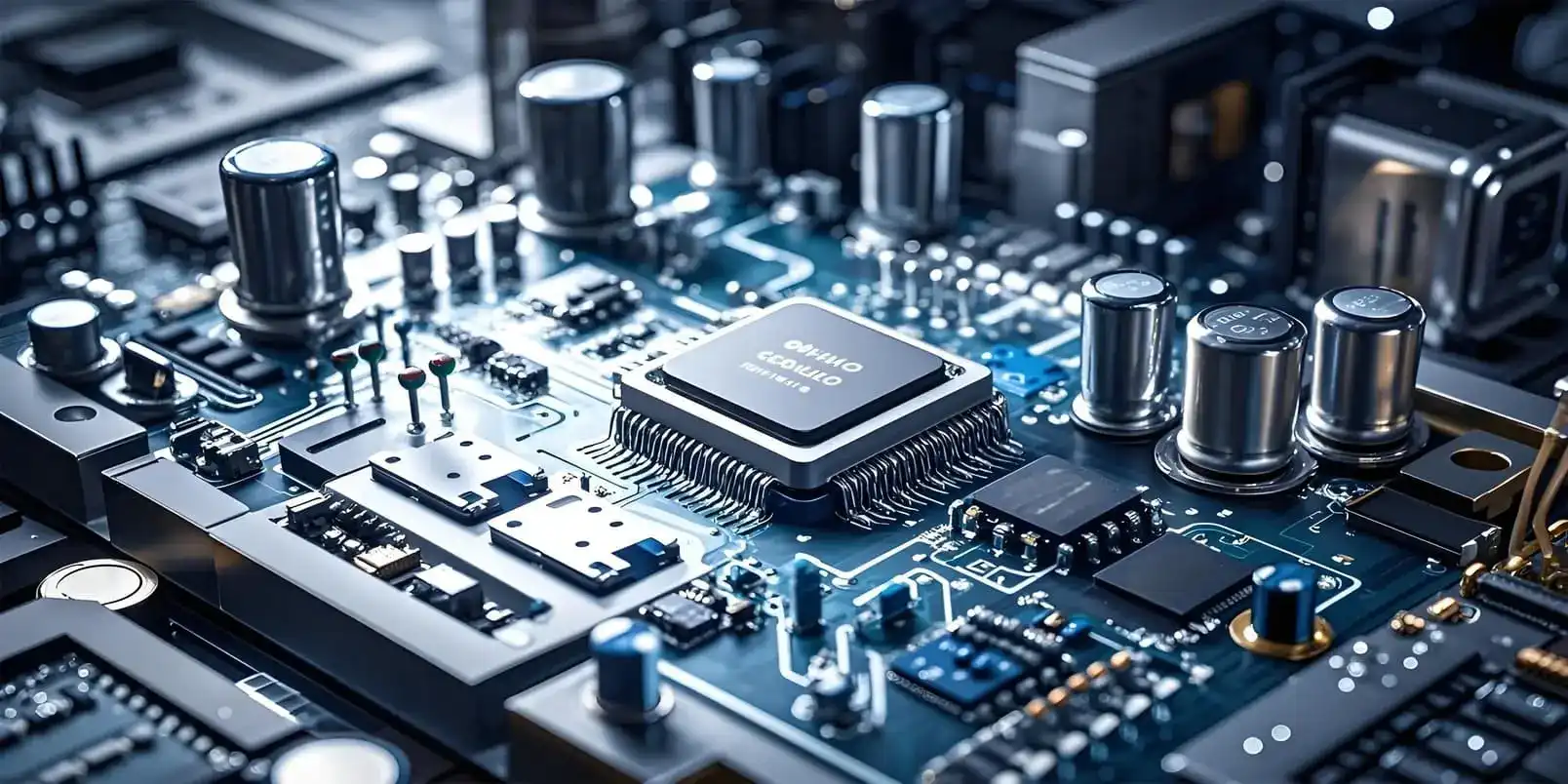

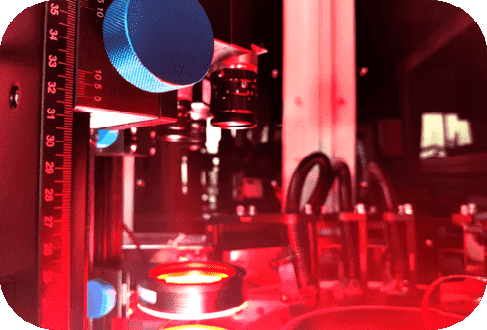

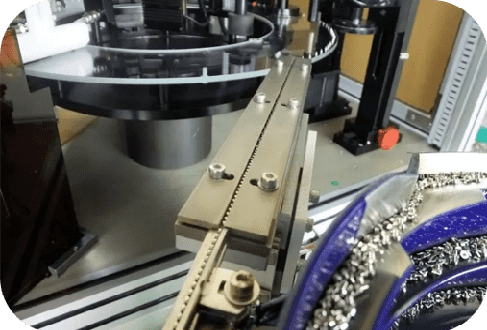

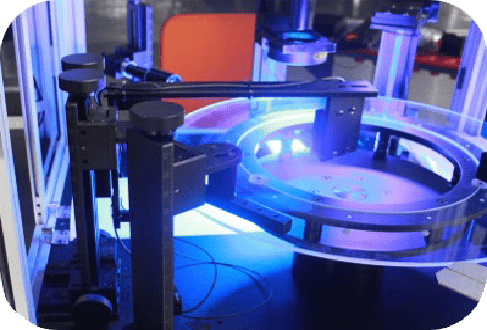

AI视觉筛选机是融合先进机器视觉与人工智能(如深度学习)的自动化检测设备。它通过高清工业相机拍摄产品图像,利用AI算法进行实时智能分析,精准识别外观缺陷(如划痕、污渍、裂纹)、尺寸偏差、装配错误、字符缺失等多种问题,并自动分类或剔除不良品。广泛应用于电子、汽车、医药、食品包装、精密制造等行业质检环节。

The AI visual inspection system integrates advanced machine vision and artificial intelligence (such as deep learning) into an automated detection device. It captures product images via high-definition industrial cameras, utilizes AI algorithms for real-time intelligent analysis, and accurately identifies various issues including surface defects (e.g., scratches, stains, cracks), dimensional deviations, assembly errors, and missing characters. It then automatically sorts or rejects defective products. This technology is widely applied in quality control processes across industries such as electronics, automotive, pharmaceuticals, food packaging, and precision manufacturing.

自动化及黑灯工厂 Automation and Black Light Factory

在产品制造过程的视觉检测筛选,自动识别,自动定位等核心方案解决。

Delivering core solutions for visual inspection screening, automated recognition, and precision positioning in manufacturing processes.

视觉检测测量 Vision-Based Inspection & Metrology System

超高检测精度和超快处理速度,实现高质量和高效率生成。

Achieve high-quality and high-efficiency production through ultra-high detection accuracy and ultra-fast processing speed.

仓储物流应用 Storage and Logistics Applications

物品出入库识别、码放引导;分拣与拆码垛引导

Identification and coding guidance for incoming and outgoing inventory of items; Sorting and palletizing guidance

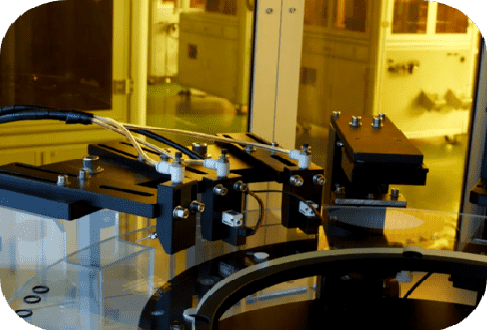

图像影像测量仪

Vision Measuring System

将显微镜,千分尺,游标卡尺,投影仪,轮廓仪,集成成一台系统解决传统的难题,做到真正意义上的一键多功能测量。Integrates microscopes, micrometers, vernier calipers, projectors, and profilometers into a unified system to resolve traditional measurement challenges, enabling truly one-button multifunctional measurement.

立卧两用,一键测量 Vertical/Horizontal Operation, One-Touch Measurement

便捷 Efficient

任何人都能轻松地进行设定和测量

Intuitive setup and measurement for operators of all skill levels

虚拟线、虚拟点的测量也能简单设定

Streamlined virtual geometry measurement with simplified configuration

所有操作都能在屏幕上进行确认,任何人都能轻松设置

Visually guided interface enables error-proof operation by all users

快速 Rapid

无需对测量对象和原点进行定位

No positioning required for measured objects or origin points

可同时测量多个目标尺寸

Simultaneous measurement of multiple target dimensions

一次性识别图像后全部测量

Complete all measurements following single image acquisition and identification.

精准 Precise

一键测量轻松操作,并获得稳定的结果

Single-button, hassle-free operation with consistent results..

不会因调整焦点而造成偏差

Defocusing-induced deviation is eliminated.

自动识别测量部位,每次都能获得统一的结果

Automated feature recognition ensures measurement repeatability across cycles.

项目案例 Our Case

探索新机会 Explore New Opportunities

- 中文: 本作品属于www.Ai-VisionTech.com原创,版权归www.Ai-VisionTech.com所有,严禁商用,如果您有任何问题,请联系info@Ai-VisionTech.com,谢谢。

- English: The information is original and copyrighted by www.Ai-VisionTech.com. Commercial use is strictly prohibited. If you have any questions, please contact us info@Ai-VisionTech.com Thank you.

- Spanish: Este producto es original de Ai-VisionTech.com, todos los derechos de autor Ai-VisionTech.com, solo para uso privado. si tiene alguna pregunta, Póngase en contacto con nosotros. info@Ai-VisionTech.com , gracias.

- French: Ce produit est original Ai-VisionTech.com, copyright Ai-VisionTech.com, pour un usage privé uniquement, contactez – nous pour toute question info@Ai-VisionTech.com Merci.

- Arabic: هذا المنتج هو Ai-VisionTech.com الأصلي ، حقوق الطبع والنشر Ai-VisionTech.com للاستخدام الخاص فقط ، إذا كان لديك أي استفسار ، يرجى الاتصال بنا info@Ai-VisionTech.com شكرا.

- German: Dieses Werk ist original und urheberrechtlich geschützt von www.Ai-VisionTech.com. Kommerzielle Nutzung ist strengstens untersagt. Wenn Sie Fragen haben, kontaktieren Sie uns bitte info@Ai-VisionTech.com Danke.

- Russian: Этот продукт для Ai-VisionTech.com Оригинал, авторские права Ai-VisionTech.com, только для частного использования, если у вас есть вопросы, пожалуйста, свяжитесь с нами info@Ai-VisionTech.com Спасибо.

- Japanese: 本作品はwww.Ai-VisionTech.comオリジナルで、著作権はwww.Ai-VisionTech.comの所有であり、商用は厳禁です。何か問題があれば、連絡してくださいinfo@Ai-VisionTech.comあ、ありがとう。

- Korean:이 작품은 www.Ai-VisionTech.com 오리지널에 속하며 저작권은 www.Ai-VisionTech.com 소유이며 상업용이 금지되어 있습니다. 문제가 있으면 연락 주십시오.info@Ai-VisionTech.com고맙습니다.

- Italy:Questo lavoro è originale e protetto da copyright da www.Ai-VisionTech.com. L’uso commerciale è severamente vietato. Se avete domande, vi preghiamo di contattarci info@Ai-VisionTech.com Grazie.

- Indonesian:Pekerjaan ini adalah asli dan hak cipta oleh Ai-VisionTech.com. Penggunaan komersial sangat dilarang. Jika Anda memiliki pertanyaan, silakan hubungi kami info@Ai-VisionTech.com Terima kasih. Terima kasih.

- Vietnamese:Tác phẩm này thuộc về www.Ai-VisionTech.com gốc và bản quyền thuộc về www.Ai-VisionTech.com, thương mại bị nghiêm cấm, nếu bạn có bất kỳ câu hỏi nào, vui lòng liên hệ info@Ai-VisionTech.com Cảm ơn.